Latine

Latine-

English

English -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик -

Español

Español -

Português

Português

Home

>

Products > Conversus et Milling Combinatae quaevis

>

Automatic cnc conversus et milling apparatus

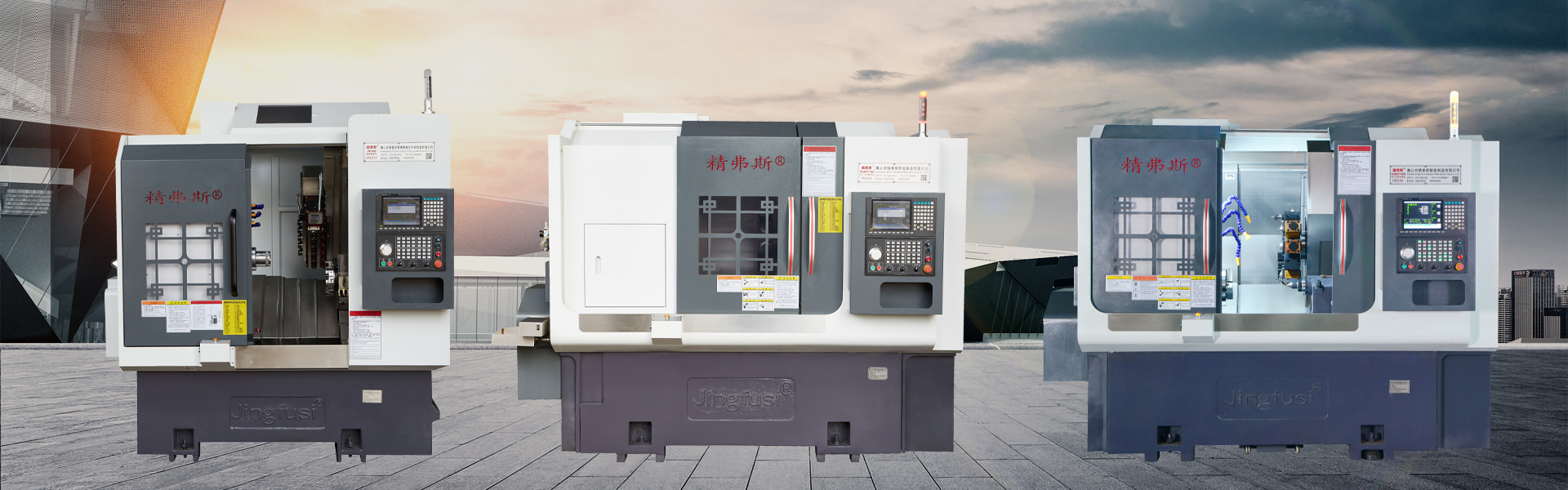

Automatic cnc conversus et milling apparatus

Automatic cnc conversus et milling apparatus est provectus vestibulum apparatu late in variis industries ut aerospace, automotive et praecisione Engineering ad efficientem productionem complexu et coetus. Hoc apparatus combines conversus et milling munera in unum unitas, providing versatility et auctus productivity.

Model:CK46-4+4+Y

Mitte Inquisitionem

depictio producti

Hi automatic CNC conversus et milling machinis instructa cum computer numeralis imperium ratio, quae permittit precise et automated machining operationes. Operators utor CAD / Cam software est progressio machina ad speciem desideravit pars dimensiones et tool semitas.

Haec automatic CNC conversus et milling machinis potest praestare conversus et milling operationes. Conversa involves gyrari workpiece dum secans instrumentum figuras in materia, cum milling involves a stationarius workpiece et circumducitur cutting instrumentum.

Haec automatic CNC conversus et milling machinis potest praestare conversus et milling operationes. Conversa involves gyrari workpiece dum secans instrumentum figuras in materia, cum milling involves a stationarius workpiece et circumducitur cutting instrumentum.

Machina Travel Diagram

Product Details

Parameter List

| item | Model of Lathe | unitas | CK46-4 + IV + | CK52-4 + IV + y |

| Processing scope | Lectus in lecto | mm | Dø D | |

| Maxime conversus exteriores circuli longitudinem | mm | 320 | ||

| Maximum Bar diameter | mm | Diam XLV | Diam LI LV | |

| principalem axem | Type fusum caput |

|

A2-5 | A2-6 |

| Fusum per-foraminis diameter | mm | Diam LVI | Diam LXVI | |

| Maximum Spindle celeritate | R / min | (VI) (Set (IV) D) | (IV) D (Pone ad MMMD) | |

| pascere | Efficens Travel ex X / Z / Axis A | mm | 800/470/260 | |

|

Maxime ieiunium motus ex X / z / axis |

M / mea | XXIV (occasum XVIII) / XXIV (occasum XVIII) / XV (occasum VIII) | ||

| X / z / y axis stupra virga | mm | 32/32/25 | ||

| X / z / A axis rail | mm | 35/35/25 | ||

| CORIFER |

Octo Statio Turret | PCs | VIII statio, potest instructum cum duplex foraminis tool holders, libitum cum XII statio | |

| Caput | Power caput instrumentum tenens formam |

|

Er25 | |

| Power caput tool | PCs | Z-Axis IV + X-axis IV, cum IV additional fixum tool holders installed | ||

| Maxime celeritas potentia caput | R / min | (VI) (set ad (IV)), potest esse communiter ad processu products ex (IV) | ||

| Intervallum inter potentia caput sagittam et hastile | mm | 65 | ||

| electrica machinery | Main motricium potentia / Torque | KW / NM | Generatio 7.5KW, 47.75nm. Steel partes cum processus facultatem in super LXXX potest esse optionally instructi 11kw, 70.03nm | |

| X / z / y axis motricium potentia / torque | KW / NM | 1.3KW / 8.39NM | ||

| X / Z Power caput motricium potentia / Torque | KW / NM | 1.7 KW / 8NM | ||

| Maxime celeritas potentia caput motricium | R / min | 5000 | ||

| alius | Fusum positioning fregit fabrica |

|

HYDRAULICUS | |

| Lecto inclinatio | ° | XXXV ° | ||

| Apparatus instrumentum longitudinem x latitudine x altitudine | mm | 2200x1580xx1900 | ||

| Totalis pondus totius machinae | Kg | 3430 | ||

| Summa | KW | 13 | ||

| Mediocris potentia consummatio | KW / h | 2 | ||

Machina tool accurate

| Apparatus accurate, Jingfus factor Latin: | ||||||||

| Maior test item | Schematic diagram | Factory vexillum | ||||||

| Fusum radialis pulsu |

|

Deprehendere runout de pyramidis | 0.0035 | |||||

| X Axis repetere situ |

|

Deprehendere repetita positioning X axis. Nota primum praedicere de L temporibus offset error frigoris engine calidum engine et deprehendere repetita positioning. | 0.003 | |||||

| Z-axis repetere situ |

|

Detect repetita positioning in z axis. Nota primum praedicere de L temporibus offset error frigoris engine calidum engine et deprehendere repetita positioning. | 0.003 | |||||

| Y Axis repetere situ |

|

Deprehendere repetita positioning in axis y. Nota primum praedicere de L temporibus offset error frigoris engine calidum engine et deprehendere repetita positioning. | 0.004 | |||||

| C axis repetere situ |

|

Detect repositioning C-Axis fixum punctum note: primum praedicere de L temporibus offset errorem frigoris engine et calidum engine et deprehendere repetita positioning | XX arcu seconds | |||||

| C axem positus gyratorius |

|

Deprehendere temere situ accurate C-Axe, Nota: primo praedicere de L temporibus offset errorem frigoris engine calidum engine et reprimendam repetita occasus | LXXII arcum seconds | |||||

| Power caput clamping beat |

|

Pulchra | 0.015 | |||||

| Power caput clamping beat |

|

Clamping verberans | 0.01 | |||||

| Si mos vult temptare ISO vel VD1 accurate X / Z / Axis AXIS, erit determinari tempore scribere contractus. Et mos est probare hoc item simul in initial acceptatio Jingfusi Factory. | ||||||||

Hot Tags: Automatic Cnc conversus et Milling Machina, Sina, Manufacturers, Suppliers, Factory, Quality, Price List

Product Tag

Mitte Inquisitionem

Libenter placet, ut inquisitionem tuam in forma infra exhibeas. Respondebimus tibi in 24 horis.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy