Latine

Latine-

English

English -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик -

Español

Español -

Português

Português

Home

>

Products > Conversus et Milling Combinatae quaevis

>

Summus celeritate conversus et milling machina

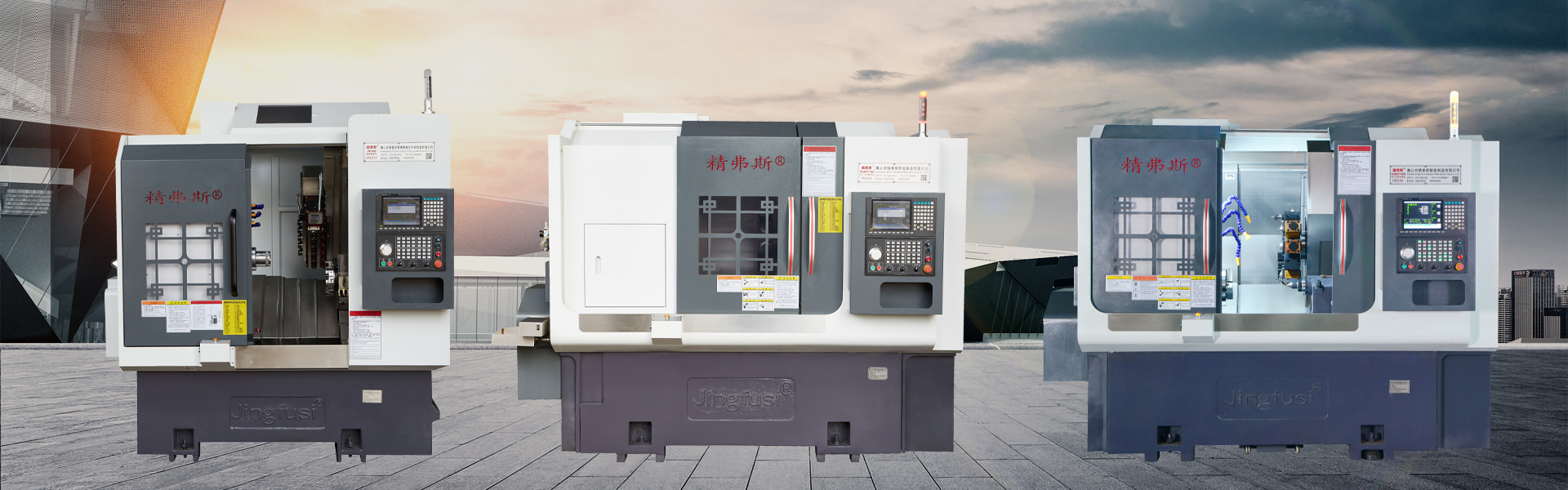

Summus celeritate conversus et milling machina

Et summus celeritate conversus et milling apparatus est a sophisticated cnc (computatrum numerical potestate) machina tool quod combines ad capabilities of a torreo (conversus) et milling apparatus. These machines are designed for precision machining operations and are often used in industries where high accuracy and efficiency are essential.You can rest assured to buy High-Speed Turret Turning and Milling Machine from our factory and we will offer you the best after-sale service and timely delivery.

Model:CK52DTY

Mitte Inquisitionem

depictio producti

Sicut professionalis manufacturer, volumus providere vobis summus celeritate conversus et milling apparatus. Et offerimus optimum post-venditionem servitium et opportune partus.

Hic sunt quidam key features et characteres summus celeritate conversus et milling machinis:

Turret Tooling: Haec machinis typically habere tool turris potest tenere multiple secans instrumenta. Turret potest esse iudex automatice eligere convenientem instrumentum pro specifica machining operationem, redigo setup tempus et augendae versatility.

Conversus capability: summus celeritate conversus et milling machinas potest praestare convertendo operationes, quae involvunt circumducitur workpiece dum secans instrumentum removet materiam creare cylindricum et conicis figuris. Hoc est utile ad producendo partes cum gyratoribus symmetria.

Milling facultatem: hae machinas potest etiam praestare milling operationes, quae involvere removere materiam ex workpiece movens in cutting tool in variis directiones. Milling concedit pro creatione complexu figuris, features et contours.

CNC Imperium: Most Modern Turres Conversio et Milling machinis sunt continentur Cnc systems. Cnc technology enables praecise imperium of tool motus et machining processuum, cursus accurate et repeatability.

Live tooling: Quidam machinis instructa cum vivet Tooling capabilities. Live tooling concedit milling operationes ad fieri dum workpiece est rotating, expanding apparatus est scriptor capabilities et reducendo opus multiple setups.

Automatic instrumentum mutationes: Multi ex his machinis feature automatic tool, quae potest cito et automatice PERMUTO ex tools in Turret, permittens enim continua machining sine manual instrumentum mutationes.

Applications: High-Celeritas Turres conversus et Milling Morte Find Applications in Industries quod requirere summus praecisione components, ut aerospace, automotive, medicinae fabrica, et productionem complexu mechanica partium.

In summary, a summus celeritate conversus et milling apparatus est versatile cnc apparatus tool quod combines conversus et milling capabilities cum focus in summus celeritate machining. Sunt in industrias ubi productionem complexu et precise components est essentialis, et provectus features faciunt ea valuable bonorum pro modern vestibulum processus.

Conversus capability: summus celeritate conversus et milling machinas potest praestare convertendo operationes, quae involvunt circumducitur workpiece dum secans instrumentum removet materiam creare cylindricum et conicis figuris. Hoc est utile ad producendo partes cum gyratoribus symmetria.

Milling facultatem: hae machinas potest etiam praestare milling operationes, quae involvere removere materiam ex workpiece movens in cutting tool in variis directiones. Milling concedit pro creatione complexu figuris, features et contours.

CNC Imperium: Most Modern Turres Conversio et Milling machinis sunt continentur Cnc systems. Cnc technology enables praecise imperium of tool motus et machining processuum, cursus accurate et repeatability.

Live tooling: Quidam machinis instructa cum vivet Tooling capabilities. Live tooling concedit milling operationes ad fieri dum workpiece est rotating, expanding apparatus est scriptor capabilities et reducendo opus multiple setups.

Automatic instrumentum mutationes: Multi ex his machinis feature automatic tool, quae potest cito et automatice PERMUTO ex tools in Turret, permittens enim continua machining sine manual instrumentum mutationes.

Applications: High-Celeritas Turres conversus et Milling Morte Find Applications in Industries quod requirere summus praecisione components, ut aerospace, automotive, medicinae fabrica, et productionem complexu mechanica partium.

In summary, a summus celeritate conversus et milling apparatus est versatile cnc apparatus tool quod combines conversus et milling capabilities cum focus in summus celeritate machining. Sunt in industrias ubi productionem complexu et precise components est essentialis, et provectus features faciunt ea valuable bonorum pro modern vestibulum processus.

Machina Travel Diagram

Product Details

Parameter List

| item | Model of Lathe | unitas | Ck52dty | Ck76dty | Ck46dty |

| Processing scope | Maximam gyrationis diameter de fusum | mm | Diam DCC | ||

| Maxime conversus exteriores circuli longitudinem | mm | 520 | |||

| Maximum Bar diameter | mm | Diam LV | LXXII diam | Diam XLV | |

| principalem axem | Maximum Spindle celeritate | R / min | (IV) CC (occasum MMMD) | MMMCC (occasu MM) | (VI) (Set (IV) D) |

| Type fusum caput |

|

A2 - VI | A2 -8 | A2 - V | |

| Fusum per-foraminis diameter | mm | Diam LXVI | Diam LXXXVI | Diam LVI | |

| pascere | X / z / y axis maximum plaga | mm | CCLX / D / ± LX | ||

| XC ° Power caput transiens per centrum de fusum | mm | 30 | |||

| Maxime ieiunium motus ex X / z / axis | M / mea | XXIV (occasum XVI) / XXIV (occasum XVI) / XIV (occasum VIII) | |||

| X / z / y axis stupra virga | mm | 40 | |||

| X / z / y axis cylindro semita | mm | 35/45/35 | |||

| Power Turret |

Power Turret Model (Power Turret) | BMT | BMT55 | ||

| Power caput collet | Est | Er32 | |||

| Fixum Tool Holder Size | mm | 25x25 | |||

| Perit possessor Shank diameter | mm | Ø32 | |||

| electrica machinery | Main motricium potentia / Torque | KW / NM | 11Kw / rated 72nm | 15KW / rated 98nm | 7.5 KW / rated 47nm |

| X / z / y axis motricium potentia / torque | KW / NM | Yaskawa 2.9 KW /18.6nm,optional nova generation3.1 KW / 15nm | |||

| Power / Torque de Turret Power caput motricium | KW / NM | Generatio 3,1 KW / 15nm | |||

| Maxime celeritas de Turret Power motricium | R / min | (VI) (occasum (IV)), commune Speed≤4000 | |||

| Power caput motricium potentia / Torque | KW / NM | 3.1 KW / 15nm | |||

| Power / Torque de Turris Tool Motending motricium | KW / NM | Generation.0 KW /3.1nm | |||

| Tailstock | Tailstock plaga | mm | 520 | ||

| Maximum Hydraulicarum ictum Tailstock |

mm | 100 | |||

| Tailstock top foramen acus pyramam foraminis taper | Mk | Mohs V # | |||

| Maxime intervallum tip et Chuck | mm | 690 | |||

| alius | Fusum positioning fregit fabrica |

|

HYDRAULICUS, libitum programmable | ||

| Lecto inclinatio | ° | XXX ° aut XV ° | |||

| Apparatus instrumentum longitudinem x latitudine x altitudine | mm | 2500x1680x1900 | |||

| Totalis pondus totius machinae | Kg | 5000KG | |||

| Summa | KW | 20 | |||

| Mediocris potentia consummatio | KW / h | 3 | |||

Machina tool accurate

| Apparatus accurate, Jingfus factor Latin: | ||||||||

| Maior test item | Schematic diagram | Deprehensio modum |

Factory vexillum |

|||||

| Fusum radialis pulsu |

|

Deprehendere runout de pyramidis | 0.0035 | |||||

| X Axis repetere situ |

|

Deprehendere repetita positioning X axis. Nota primum praedicere de L temporibus offset error frigoris engine calidum engine et deprehendere repetita positioning. | 0.003 | |||||

| Z-axis repetere situ |

|

Detect repetita positioning in z axis. Nota primum praedicere de L temporibus offset error frigoris engine calidum engine et deprehendere repetita positioning. | 0.003 | |||||

| Y Axis repetere situ |

|

Deprehendere repetita positioning in axis y. Nota primum praedicere de L temporibus offset error frigoris engine calidum engine et deprehendere repetita positioning. | 0.004 | |||||

| C axis repetere situ |

|

Detect repositioning C-Axis fixum punctum note: primum praedicere de L temporibus offset errorem frigoris engine et calidum engine et deprehendere repetita positioning | XX arcu seconds | |||||

| C axem positus gyratorius |

|

Deprehendere temere situ accurate C-Axe, Nota: primo praedicere de L temporibus offset errorem frigoris engine calidum engine et reprimendam repetita occasus | LXXII arcum seconds | |||||

| Power caput clamping beat |

|

Pulchra | 0.015 | |||||

| Power caput clamping beat |

|

Clamping verberans | 0.01 | |||||

| Si mos vult temptare ISO vel VD1 accurate X / Z / Axis AXIS, erit determinari tempore scribere contractus. Et mos est probare hoc item simul in initial acceptatio Jingfusi Factory. | ||||||||

Hot Tags: High-Celeritas Turres conversus et Milling Machina, Sina, Manufacturers, Suppliers, Factory, Quality, Price List

Product Tag

Mitte Inquisitionem

Libenter placet, ut inquisitionem tuam in forma infra exhibeas. Respondebimus tibi in 24 horis.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy